Product Details

Place of Origin: CHINA

Brand Name: ACC Machine

Certification: CE

Model Number: FLD-45N

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: 22000 USD per set

Packaging Details: wood box package

Delivery Time: 5-8 work days

Payment Terms: T/T

Supply Ability: 30 days per set

|

Customization:

|

Highly Customized Equipment

|

Product Examples:

|

Film, Pipe, Board, Thread, Tape, Granule

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

Reduction Gearbox:

|

GUOMAO

|

Temperature Controller:

|

RKC Or OMRON Brand

|

Product Name:

|

Plastic Nose Wire/Bridge Making Production Line

|

Hard Toothed Gearbox:

|

High Stability And Low Noise

|

Extruder Barrel Material:

|

38CrMoAlA

|

|

Customization:

|

Highly Customized Equipment

|

|

Product Examples:

|

Film, Pipe, Board, Thread, Tape, Granule

|

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

|

Reduction Gearbox:

|

GUOMAO

|

|

Temperature Controller:

|

RKC Or OMRON Brand

|

|

Product Name:

|

Plastic Nose Wire/Bridge Making Production Line

|

|

Hard Toothed Gearbox:

|

High Stability And Low Noise

|

|

Extruder Barrel Material:

|

38CrMoAlA

|

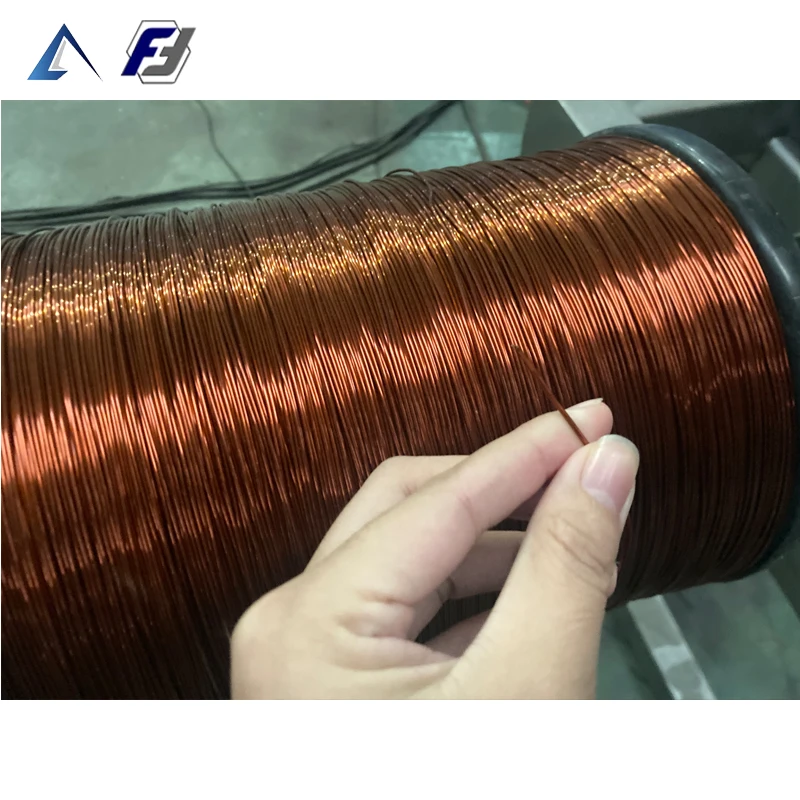

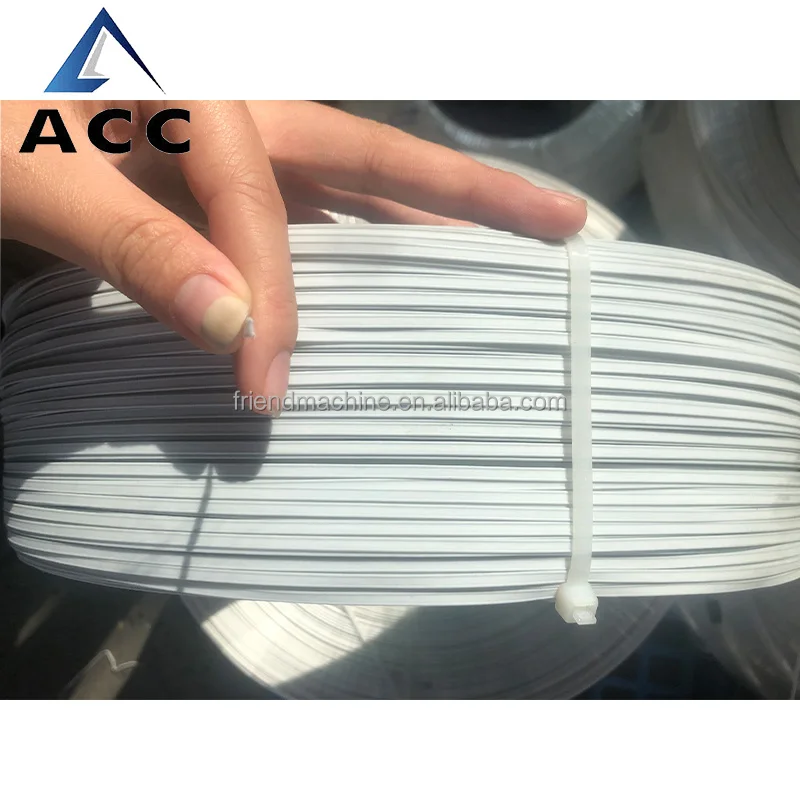

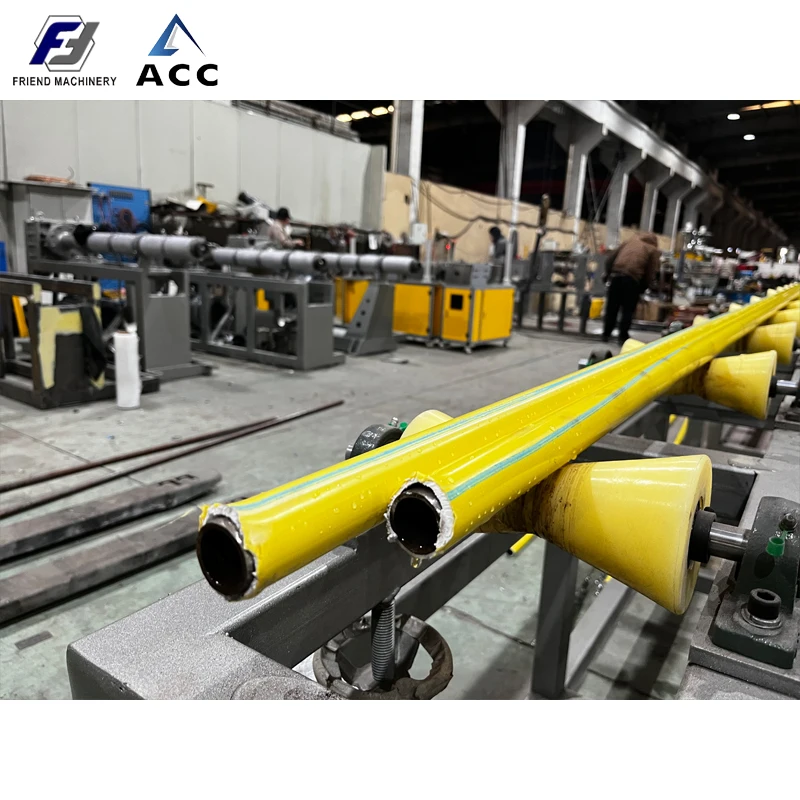

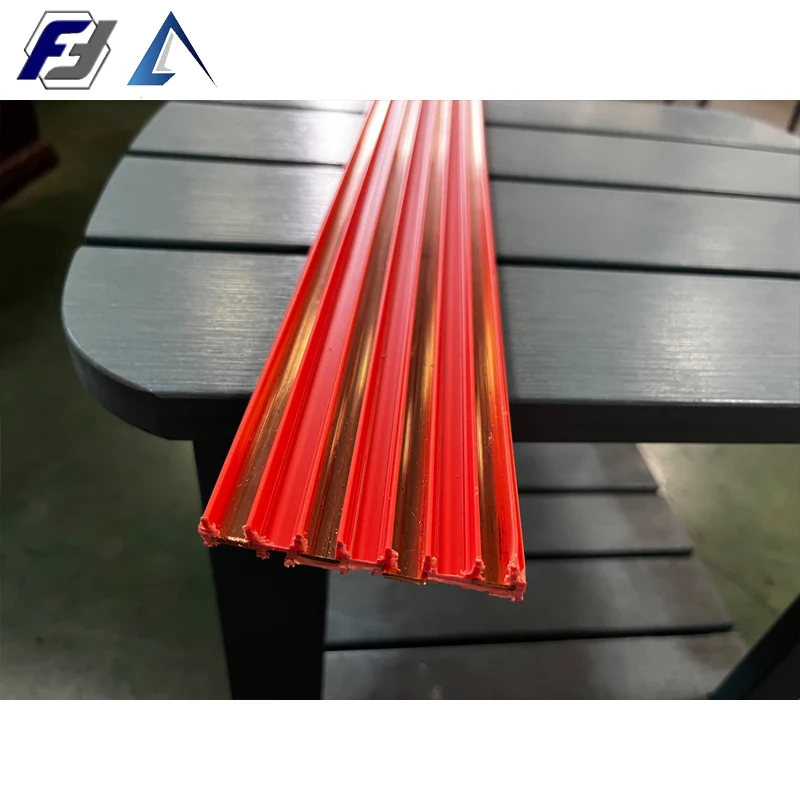

The Plastic Profile Production Line is a versatile and efficient machine designed for the production of various plastic profiles, including plastic nose wire/bridge for PP PE nose wire making production line, PVC packaging ties extrusion production line, and plastic wire making production line. This production line is available in both Automated Control and Manual Control options, providing flexibility to meet different production requirements.

Equipped with a Siemens motor, the Plastic Profile Production Line ensures reliable and high-performance operation. The use of Siemens brand motor guarantees durability and energy efficiency, contributing to cost savings and sustainable production practices.

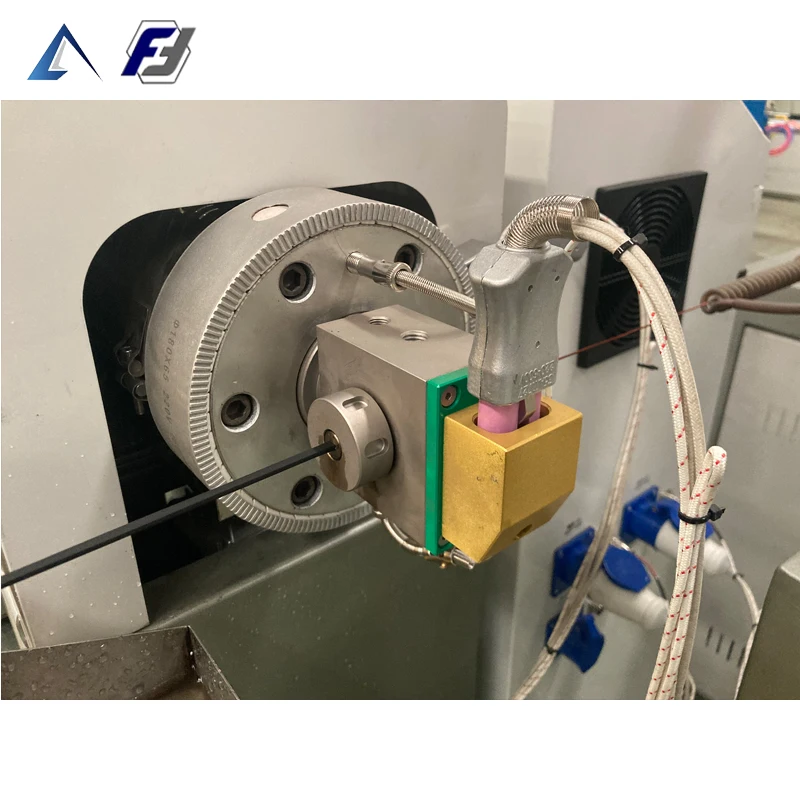

The core component of the Plastic Profile Production Line is the single screw extruder, which is designed for precision extrusion of plastic materials. The extruder barrel material is made of high-quality 38CrMoAlA, known for its excellent wear resistance and long service life. This ensures consistent and high-quality output of plastic profiles, meeting the stringent requirements of various applications.

Whether you are producing plastic nose wire/bridge for PP PE nose wire making production line, PVC packaging ties for extrusion production line, or plastic wire for general applications, the Plastic Profile Production Line offers a reliable and efficient solution. With its advanced technology and robust construction, this production line is suitable for a wide range of industries, including packaging, construction, and automotive.

Key Features of the Plastic Profile Production Line:

Overall, the Plastic Profile Production Line is a cutting-edge solution for manufacturers looking to produce high-quality plastic profiles with precision and efficiency. Whether you need to produce plastic nose wire/bridge for PP PE nose wire making production line, PVC packaging ties for extrusion production line, or other plastic profiles, this production line offers the technology and reliability you need to succeed in today's competitive market.

| Weight | 2-10T |

| Auxiliary Machines | Die head for producing various plastic products |

| Output Capacity | 40kg/ Hr |

| Type | Automated Control Or Manual Control |

| Package | Stretch Film Packaging |

| Hard Toothed Gearbox | High Stability And Low Noise |

| Customization | Highly customized equipment |

| Product Description | Plastic coating making production line |

| Cooling Water Tank | Made Of Stainless Steel Material |

| Line Speed | 80-100m/min |

ACC Machine offers the FLD-45N Plastic Profile Production Line, a versatile and high-quality solution for various industries. This production line is CE certified and originates from China, ensuring reliability and efficiency. With a minimum order quantity of 1 set and a price of 22000 USD per set, it offers great value for the features it provides.

The Plastic Profile Production Line is ideal for a range of applications, making it a valuable asset in industries such as wires and cables, optical fibers, auto parts, and construction materials. The extruder is suitable for extruding thermo-plastics like PVC, PP, PE, PP-R, and ABS, making it a versatile choice for different production needs.

One of the key features of this production line is its high line speed of 80-100m/min, allowing for efficient and speedy production. The output capacity of 40kg/hr ensures a consistent and reliable performance, meeting the demands of various production scenarios.

Whether you need to produce dual-core nose wire, single core ties, or PP PE nose wire, this production line can handle the task effectively. The machine is designed to meet the specific requirements of each application, providing precision and quality output.

With a supply ability of 30 sets per month and a delivery time of 5-8 work days, ACC Machine ensures prompt delivery to meet your production timelines. The packaging details include a wood box package for secure transportation, giving you peace of mind when receiving your equipment.

Invest in the ACC Machine FLD-45N Plastic Profile Production Line for a reliable, efficient, and high-performance solution for your production needs. With T/T payment terms and exceptional after-sales support, you can trust in the quality and service provided by ACC Machine.

Our Product Technical Support and Services for the Plastic Profile Production Line include:

- Installation and setup guidance

- Operator training and maintenance support

- Troubleshooting assistance for any issues

- Regular maintenance checks and servicing

- Access to online resources and documentation

Product Packaging:

The Plastic Profile Production Line is carefully packaged in sturdy cardboard boxes to ensure safe transportation. Each component is securely packed to prevent any damage during shipping.

Shipping Information:

We offer worldwide shipping for the Plastic Profile Production Line. Once your order is confirmed, the product will be shipped within 3-5 business days. You will receive a tracking number to monitor the delivery status of your package.

Q: What is the brand name of this Plastic Profile Production Line?

A: The brand name is ACC Machine.

Q: What is the model number of this Plastic Profile Production Line?

A: The model number is FLD-45N.

Q: What certification does this Plastic Profile Production Line have?

A: It has CE certification.

Q: Where is the Plastic Profile Production Line manufactured?

A: It is made in CHINA.

Q: What are the payment terms for purchasing this Plastic Profile Production Line?

A: The payment terms are T/T.