Product Details

Place of Origin: CHINA

Brand Name: ACC Machine

Certification: CE

Model Number: FLD-45N

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: 22000 USD per set

Packaging Details: wood box package

Delivery Time: 5-8 work days

Payment Terms: T/T

Supply Ability: 30 days per set

|

Extruder Type:

|

Single Screw Extruder

|

Core Components:

|

Unloading System, Pre-treatment System, Extruder, Coating Mold, Cooling System, Traction Device, Cutting Or Winding Device And PLC Control System

|

Product Category:

|

Plastic Profile Production Line

|

Temperature Controller:

|

RKC Or OMRON Brand

|

Product Examples:

|

Film, Pipe, Board, Thread, Tape, Granule

|

Reduction Gearbox:

|

GUOMAO

|

Motor:

|

Siemens Brand

|

Dimension:

|

15m*2.8m*2.5m

|

|

Extruder Type:

|

Single Screw Extruder

|

|

Core Components:

|

Unloading System, Pre-treatment System, Extruder, Coating Mold, Cooling System, Traction Device, Cutting Or Winding Device And PLC Control System

|

|

Product Category:

|

Plastic Profile Production Line

|

|

Temperature Controller:

|

RKC Or OMRON Brand

|

|

Product Examples:

|

Film, Pipe, Board, Thread, Tape, Granule

|

|

Reduction Gearbox:

|

GUOMAO

|

|

Motor:

|

Siemens Brand

|

|

Dimension:

|

15m*2.8m*2.5m

|

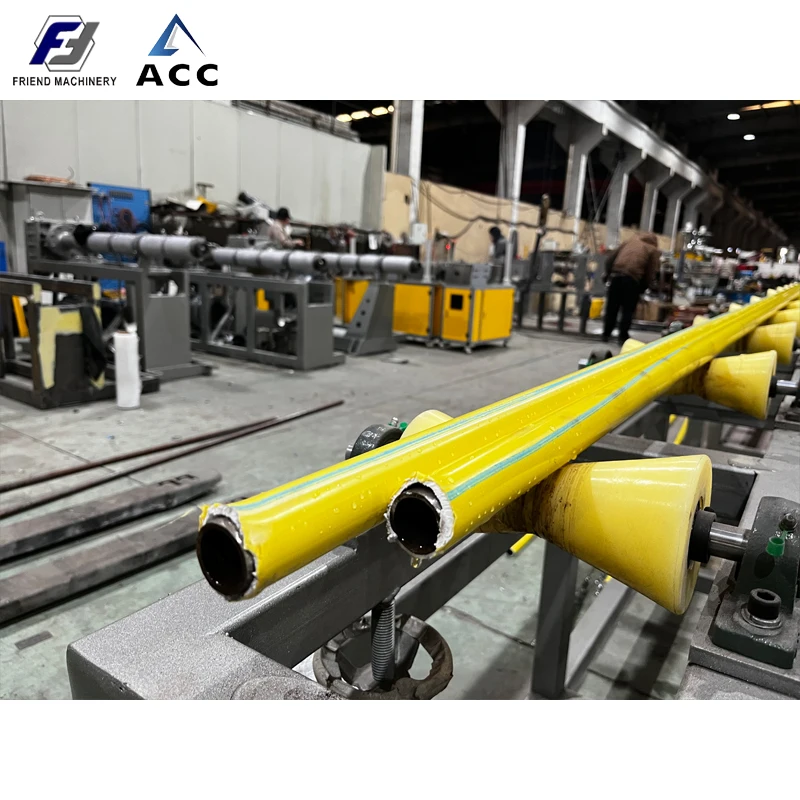

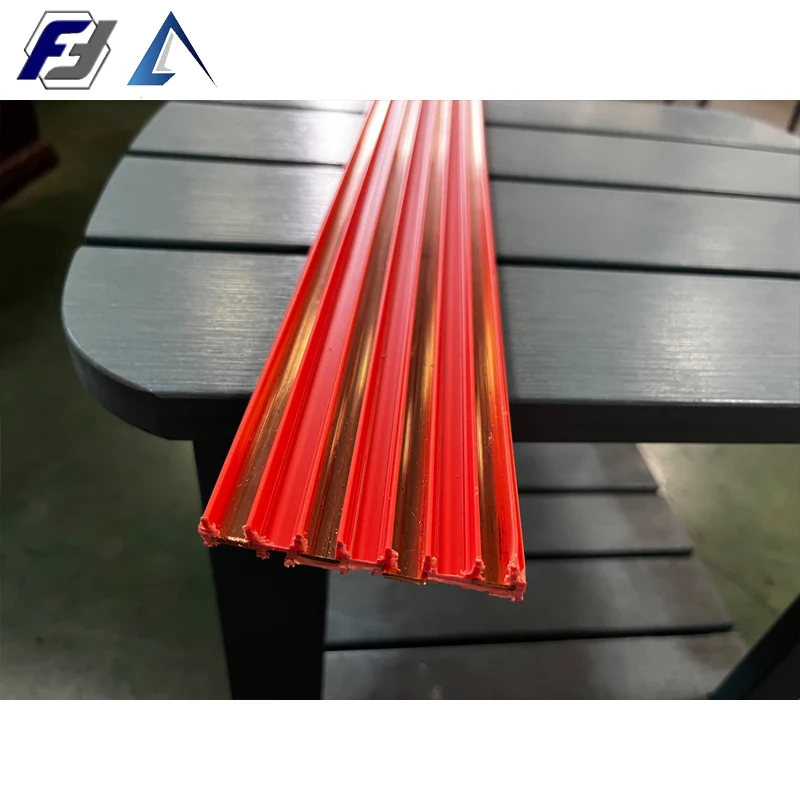

The Plastic Profile Production Line is a cutting-edge solution designed for manufacturing various plastic products with precision and efficiency. This state-of-the-art equipment is ideal for industries requiring high-quality plastic profiles, such as the steel wire coating plastic making production line.

Featuring an Independent Control Box, this production line offers enhanced operational control and flexibility. The control box allows operators to efficiently manage and monitor the entire production process, ensuring consistent output quality.

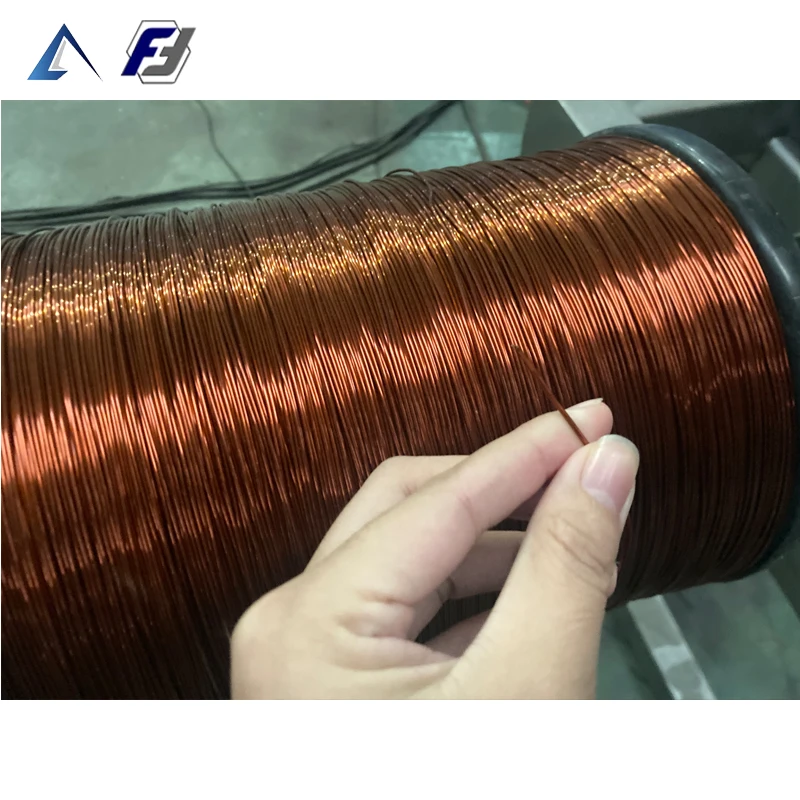

As a leading product in the Plastic Profile Production Line category, this equipment is known for its superior customization capabilities. It is a highly customized solution that can be tailored to meet specific production requirements and industry standards. Whether you need to produce Plastic wire making production line or other plastic products, this production line can be adapted to suit your unique needs.

The Cooling Water Tank of this production line is constructed from high-quality stainless steel material, ensuring durability and longevity. The tank is designed to efficiently cool the plastic profiles during the production process, maintaining optimal temperature control for consistent product quality.

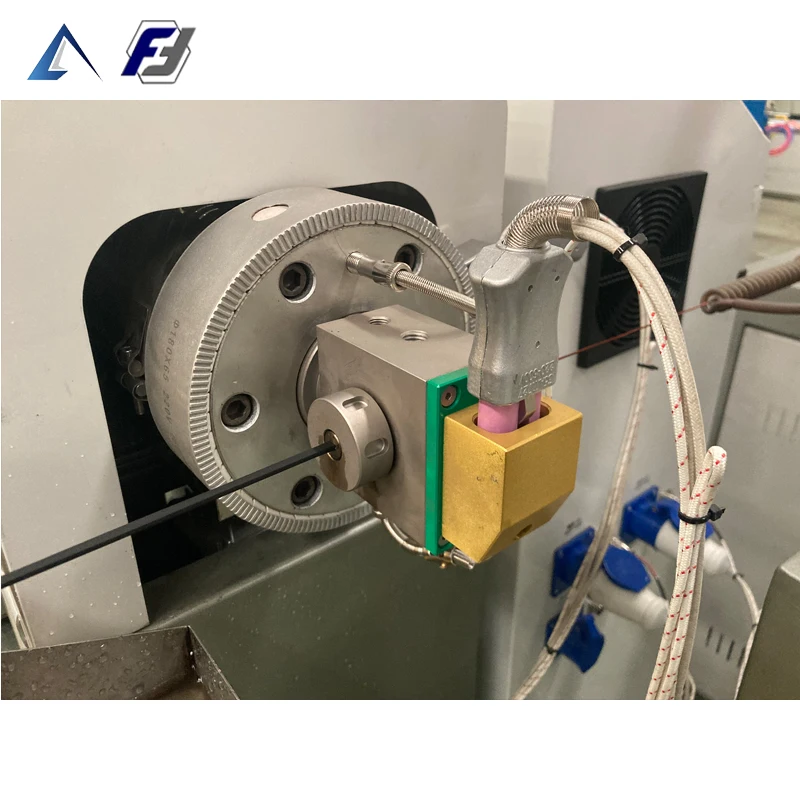

In addition to its core components, this production line also includes Auxiliary Machines such as the die head for producing various plastic products. The die head plays a crucial role in shaping and forming the plastic profiles, ensuring precise dimensions and smooth finishes. With the die head and other auxiliary machines, this production line offers a comprehensive solution for Plastic wire making production line and other plastic manufacturing needs.

| Temperature Controller | RKC Or OMRON Brand |

| Cooling Water Tank | Made Of Stainless Steel Material |

| Weight | 2-10T |

| Dimension | 15m*2.8m*2.5m |

| Extruder Usage | Extruding thermo-plastics like PVC, PP, PE, PP-R, ABS |

| Reduction Gearbox | GUOMAO |

| Auxiliary Machines | Die head for producing various plastic products |

| Motor | Siemens Brand |

| Line Speed | 80-100m/min. |

| Control Box | Independent Box |

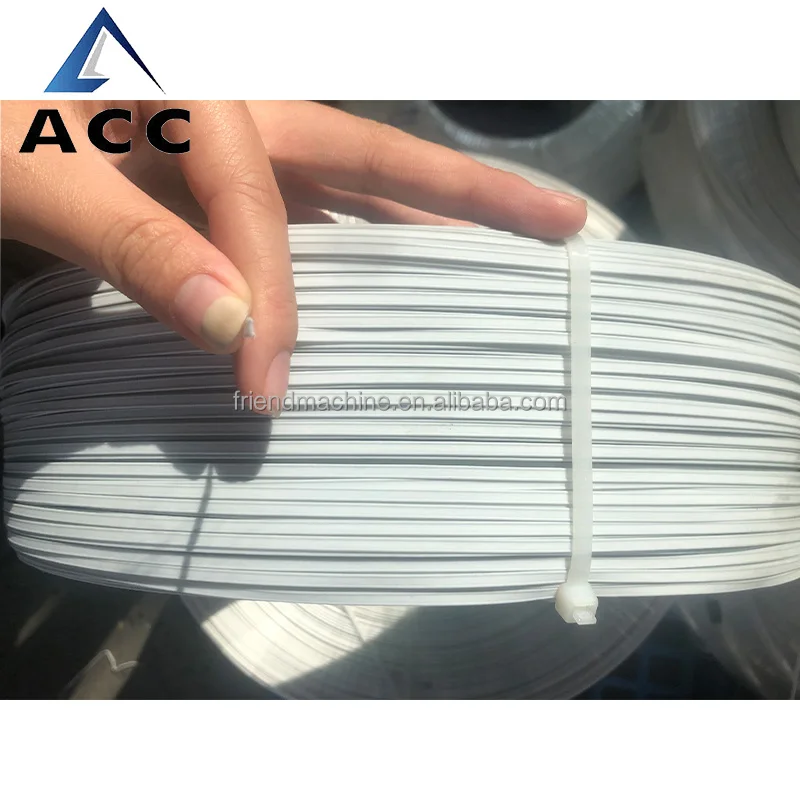

ACC Machine Plastic Profile Production Line (Model: FLD-45N) is a versatile and high-quality machine suitable for various product application occasions and scenarios. This production line is ideal for manufacturing a wide range of plastic profiles, including PVC cable ties, dual-core nose wires, and PP PE nose wires.

With CE certification and originating from China, the ACC Machine Plastic Profile Production Line guarantees reliability and quality. The minimum order quantity for this product is 1 set, priced at 22000 USD per set. Payment terms are flexible with T/T accepted, and the supply ability is 30 sets per month, ensuring quick availability.

The delivery time for the Plastic Profile Production Line is between 5-8 working days, with each set packaged securely in a wood box package for safe transportation. The machine features a Siemens brand motor and weighs between 2-10 tons, making it sturdy and durable for long-term use.

The core components of this production line include an unloading system, pre-treatment system, extruder, coating mold, cooling system, traction device, cutting or winding device, and a PLC control system. These components work seamlessly together to ensure efficient and precise production of plastic profiles.

With dimensions of 15m*2.8m*2.5m, the Plastic Profile Production Line from ACC Machine falls under the product category of Plastic Profile Production Line, catering to various industries and applications. Whether you are in the PVC cable ties making industry, dual-core nose wire manufacturing sector, or PP PE nose wire production line, this machine is designed to meet your specific production needs.

Our Product Technical Support and Services for the Plastic Profile Production Line include:

- Installation and setup guidance

- Training for operating and maintaining the production line

- Troubleshooting assistance for any technical issues

- Regular maintenance and servicing recommendations

- Access to software updates and technical documentation

We are committed to ensuring that your Plastic Profile Production Line operates efficiently and effectively, providing you with the support you need to maximize its performance.

Product Packaging:

The Plastic Profile Production Line is carefully packaged to ensure safe transportation and delivery. Each component of the production line is securely wrapped and protected to prevent any damage during shipping. The packaging is designed to withstand handling and storage, keeping the equipment in optimal condition until it reaches its destination.

Shipping Information:

Once your order is processed, the Plastic Profile Production Line will be shipped via a reliable and efficient carrier service. You will be provided with a tracking number to monitor the status of your shipment. Please ensure someone is available to receive and sign for the delivery to avoid any potential delays.

Q: What is the brand name of the Plastic Profile Production Line?

A: The brand name of the Plastic Profile Production Line is ACC Machine.

Q: What is the model number of the Plastic Profile Production Line?

A: The model number of the Plastic Profile Production Line is FLD-45N.

Q: What certification does the Plastic Profile Production Line have?

A: The Plastic Profile Production Line is CE certified.

Q: Where is the Plastic Profile Production Line manufactured?

A: The Plastic Profile Production Line is manufactured in China.

Q: What are the payment terms for purchasing the Plastic Profile Production Line?

A: The payment terms for purchasing the Plastic Profile Production Line are T/T.