Product Details

Place of Origin: CHINA

Brand Name: ACC Machine

Certification: CE

Model Number: FLD-45N

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: 22000 USD per set

Packaging Details: wood box package

Delivery Time: 5-8 work days

Payment Terms: T/T

Supply Ability: 30 days per set

|

Type:

|

Automated Control Or Manual Control

|

Cooling Water Tank:

|

Made Of Stainless Steel Material

|

Motor:

|

Siemens Brand

|

Extruder Usage:

|

Extruding Thermo-plastics Like PVC, PP, PE, PP-R, ABS

|

Core Components:

|

Unloading System, Pre-treatment System, Extruder, Coating Mold, Cooling System, Traction Device, Cutting Or Winding Device And PLC Control System

|

Product Name:

|

Plastic Nose Wire/Bridge Making Production Line

|

Output Capacity:

|

40kg/ Hr

|

Product Category:

|

Plastic Profile Production Line

|

|

Type:

|

Automated Control Or Manual Control

|

|

Cooling Water Tank:

|

Made Of Stainless Steel Material

|

|

Motor:

|

Siemens Brand

|

|

Extruder Usage:

|

Extruding Thermo-plastics Like PVC, PP, PE, PP-R, ABS

|

|

Core Components:

|

Unloading System, Pre-treatment System, Extruder, Coating Mold, Cooling System, Traction Device, Cutting Or Winding Device And PLC Control System

|

|

Product Name:

|

Plastic Nose Wire/Bridge Making Production Line

|

|

Output Capacity:

|

40kg/ Hr

|

|

Product Category:

|

Plastic Profile Production Line

|

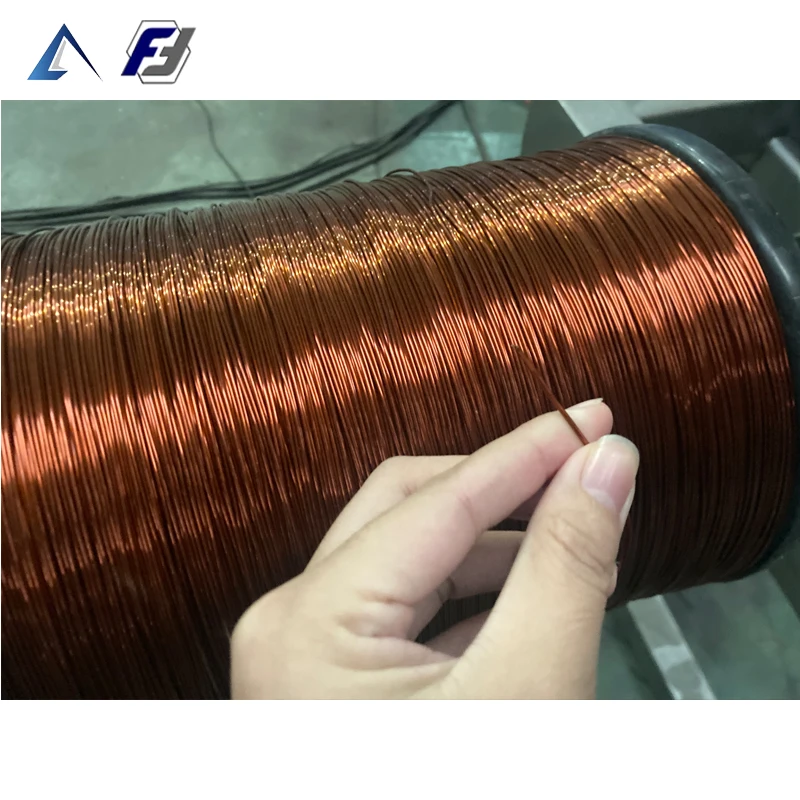

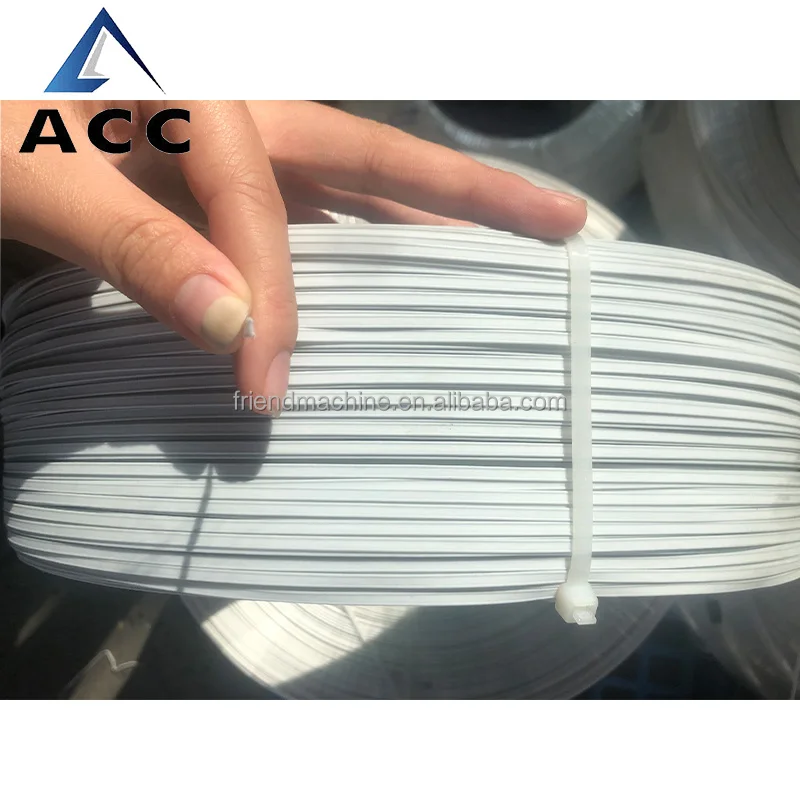

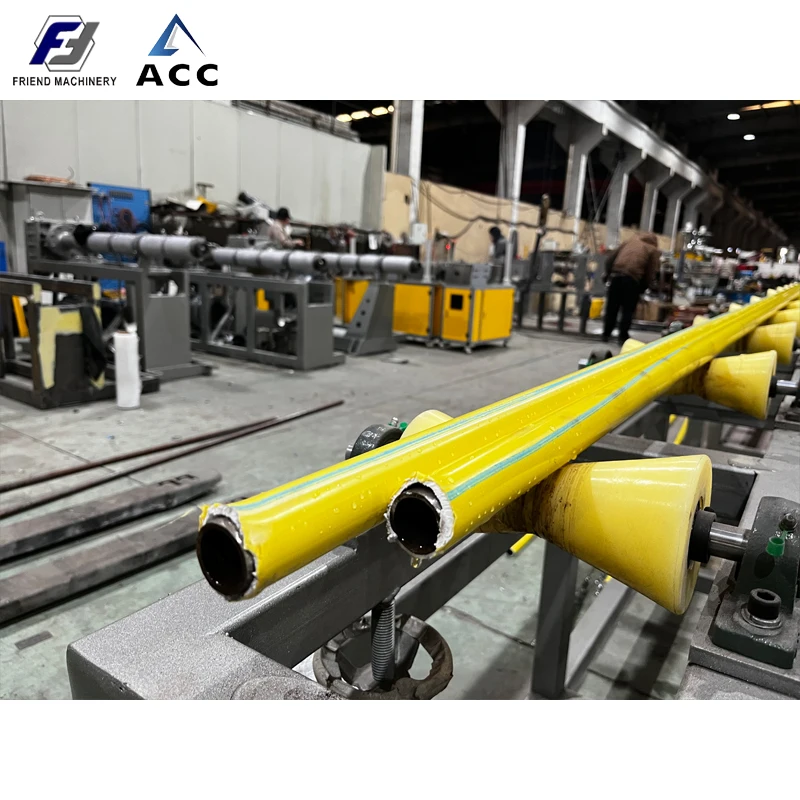

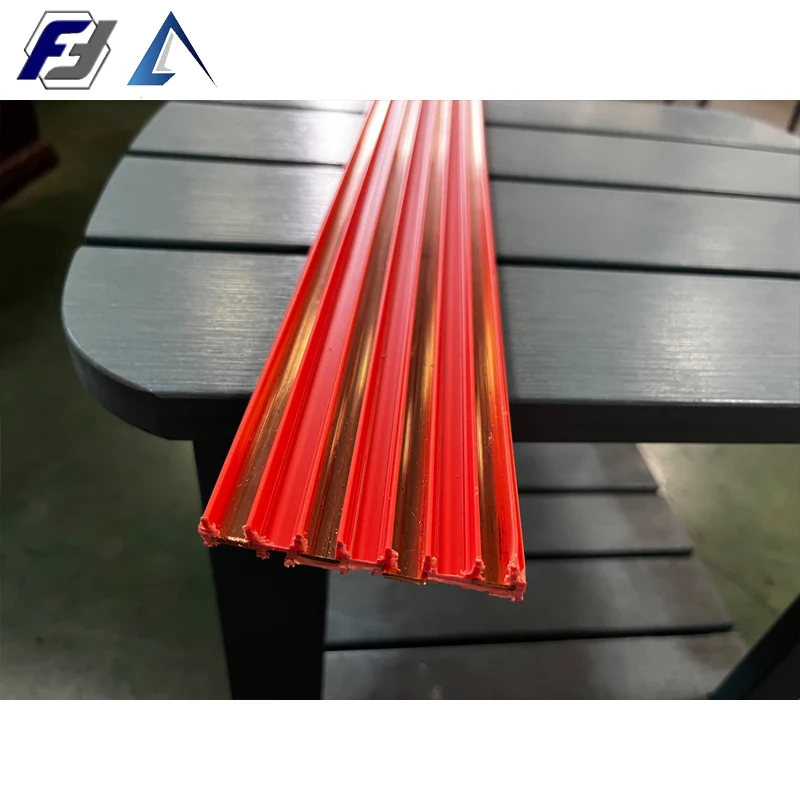

The Plastic Profile Production Line is a versatile manufacturing solution designed to meet various industry needs. This production line is ideal for producing a wide range of plastic profiles used in applications such as wires and cables, optical fibers, auto parts, construction materials, and more.

With its highly customized equipment, the Plastic Profile Production Line offers the flexibility to meet specific production requirements. Whether it is for plastic wire making production line, PP PE nose wire making production line, or single core ties making machine, this production line can be tailored to suit individual needs.

Depending on the preference and operational requirements, the Plastic Profile Production Line can be configured for either automated control or manual control. This flexibility allows for seamless integration into different manufacturing environments, ensuring optimal efficiency and productivity.

The Plastic Profile Production Line is packaged using stretch film packaging, providing protection during transportation and storage. This packaging method ensures that the equipment arrives safely and securely at its destination, ready for installation and operation.

| Type | Automated Control Or Manual Control |

| Motor | Siemens Brand |

| Extruder Type | Single screw extruder |

| Extruder Usage | Extruding thermo-plastics like PVC, PP, PE, PP-R, ABS |

| Product Description | Plastic coating making production line |

| Product Examples | Film, pipe, board, thread, tape, granule |

| Product Name | Plastic Nose Wire/Bridge Making Production Line |

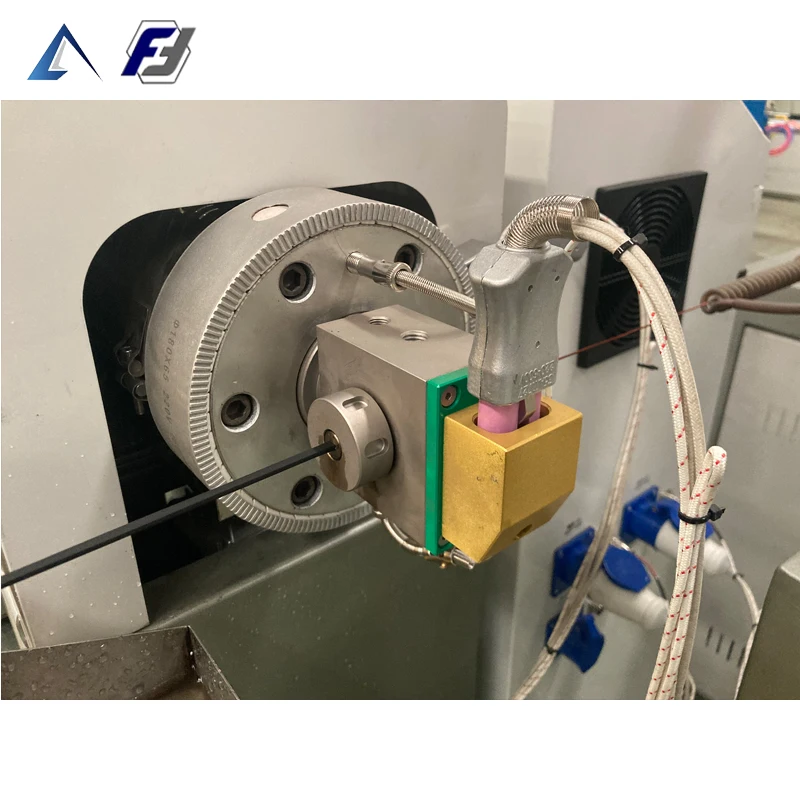

| Core Components | Unloading system, pre-treatment system, extruder, coating mold, cooling system, traction device, cutting or winding device and PLC control system |

| Product Category | Plastic Profile Production Line |

| Cooling Water Tank | Made Of Stainless Steel Material |

ACC Machine offers the FLD-45N Plastic Profile Production Line, ideal for a variety of product application occasions and scenarios. This production line is suitable for manufacturing a range of products, including steel wire coating plastic making production line, PVC Packaging ties extrusion production line, and Plastic wire making production line.

The FLD-45N Plastic Profile Production Line is certified with CE and originates from CHINA. The minimum order quantity is 1 set, with each set priced at 22000 USD. Payment terms accepted include T/T, and the supply ability is 30 days per set. Delivery time is estimated at 5-8 work days, with packaging details in wood box packaging.

This production line boasts a line speed of 80-100m/min, making it efficient for various manufacturing needs. In addition to the main machine, the FLD-45N Plastic Profile Production Line also includes auxiliary machines such as the die head for producing various plastic products.

With its high-speed capabilities and versatile applications, this Plastic Profile Production Line is a valuable asset for industries requiring precise and efficient plastic coating making production processes. The package includes Stretch Film Packaging, ensuring the safe delivery of the equipment.

The Plastic Profile Production Line product comes with comprehensive product technical support and services to ensure smooth operation and maintenance. Our team of experts is available to provide guidance on machine setup, troubleshooting, and optimization. Additionally, we offer training programs to help operators maximize efficiency and productivity. Our service team is dedicated to providing timely assistance and spare parts delivery to minimize downtime and keep your production line running smoothly.

Product Packaging:

The Plastic Profile Production Line will be carefully packaged in sturdy cardboard boxes to ensure safe transportation. Each component of the production line will be individually wrapped and cushioned to prevent any damage during shipping.

Shipping:

We offer worldwide shipping for the Plastic Profile Production Line. The product will be shipped via a reputable carrier with tracking information provided to the customer. Delivery times may vary depending on the destination, but we strive to deliver the product in a timely manner.

Q: What is the brand name of this Plastic Profile Production Line?

A: The brand name is ACC Machine.

Q: What is the model number of this Plastic Profile Production Line?

A: The model number is FLD-45N.

Q: What certification does this Plastic Profile Production Line have?

A: It is CE certified.

Q: Where is this Plastic Profile Production Line manufactured?

A: It is manufactured in CHINA.

Q: What are the payment terms for purchasing this Plastic Profile Production Line?

A: The payment terms are T/T.