Product Details

Place of Origin: CHINA

Brand Name: ACC Machine

Certification: CE

Model Number: FLD-45N

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: 22000 USD per set

Packaging Details: wood box package

Delivery Time: 5-8 work days

Payment Terms: T/T

Supply Ability: 30 days per set

|

Weight:

|

2-10T

|

Motor:

|

Siemens Brand

|

Package:

|

Stretch Film Packaging

|

Output Capacity:

|

40kg/ Hr

|

Control Box:

|

Independent Box

|

Extruder Barrel Material:

|

38CrMoAlA

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

Line Speed:

|

80-100m/min.

|

|

Weight:

|

2-10T

|

|

Motor:

|

Siemens Brand

|

|

Package:

|

Stretch Film Packaging

|

|

Output Capacity:

|

40kg/ Hr

|

|

Control Box:

|

Independent Box

|

|

Extruder Barrel Material:

|

38CrMoAlA

|

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

|

Line Speed:

|

80-100m/min.

|

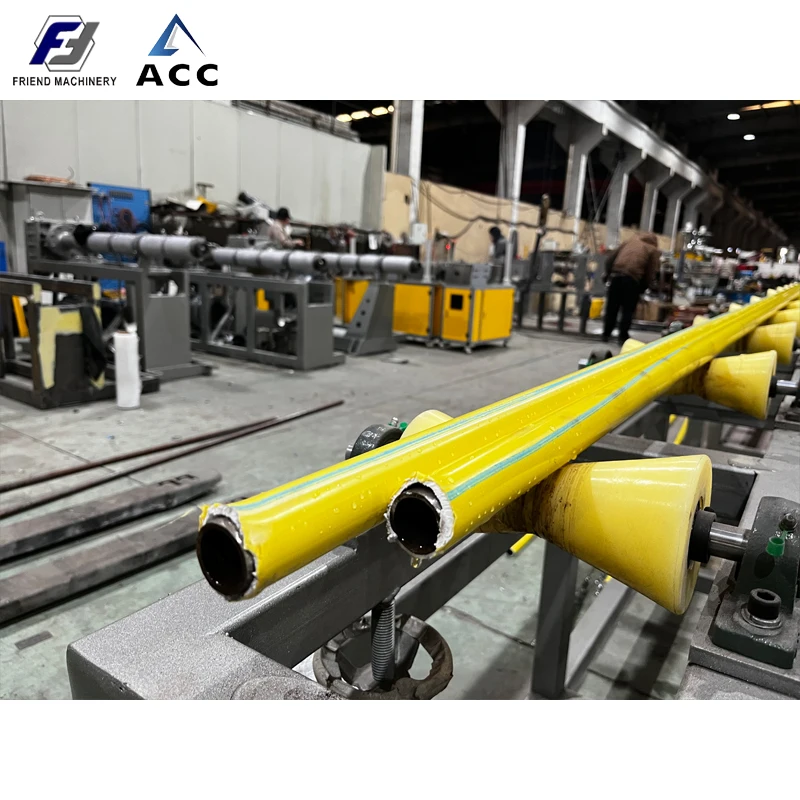

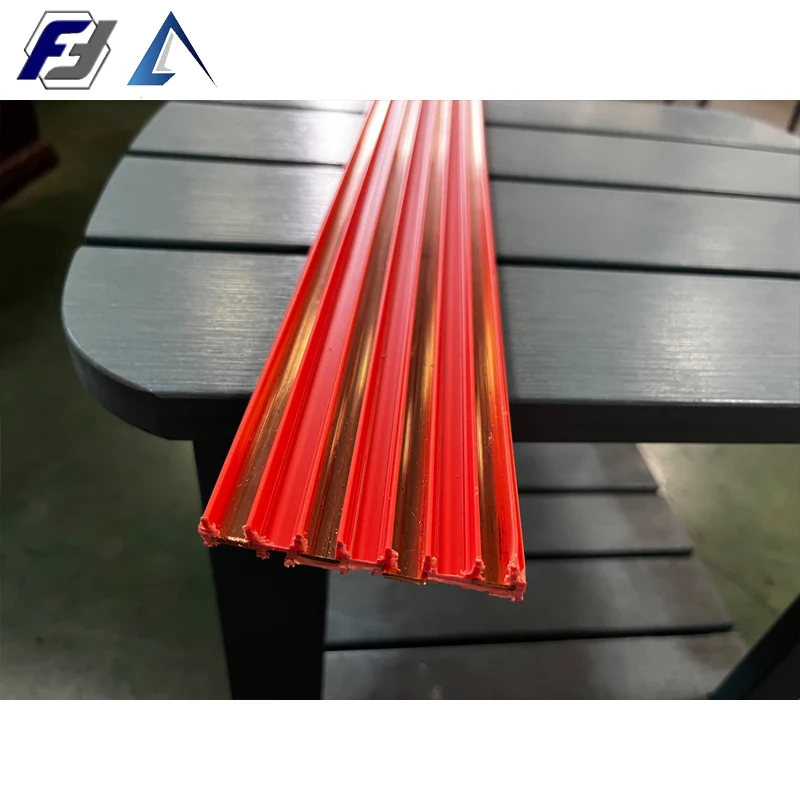

The Plastic Profile Production Line is a cutting-edge manufacturing solution designed to meet the high demands of producing a wide range of plastic products. With a line speed ranging from 80 to 100 meters per minute, this production line offers exceptional efficiency and productivity.

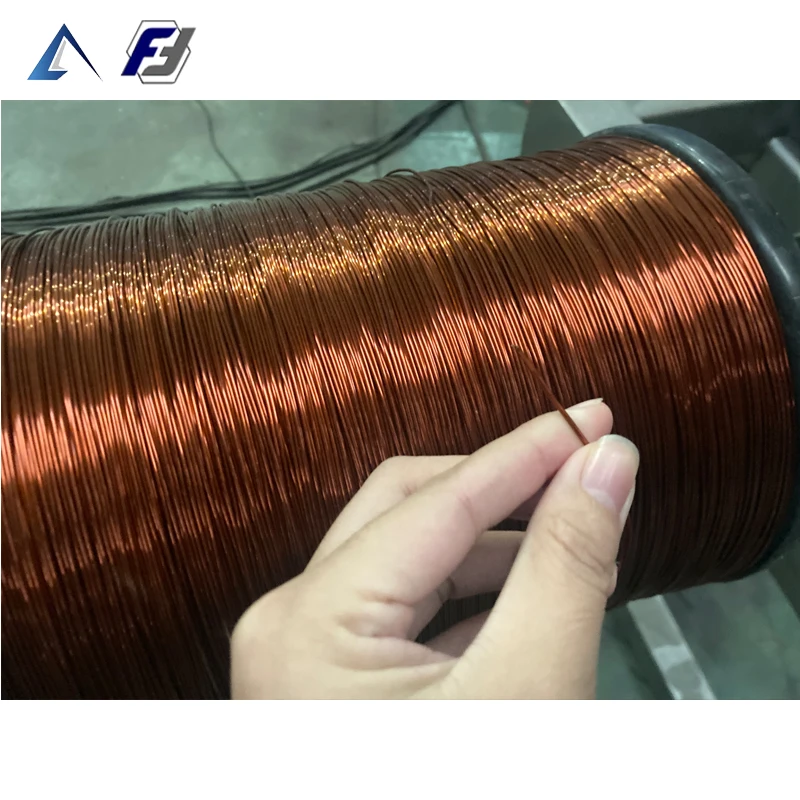

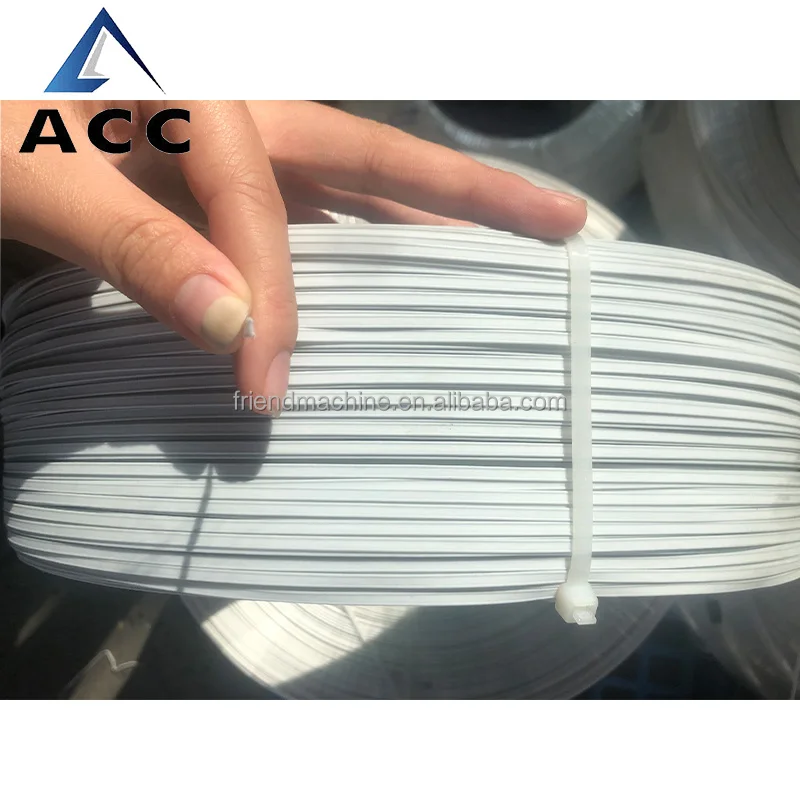

Capable of producing various plastic products such as film, pipe, board, thread, tape, and granules, this production line is versatile and adaptable to different production needs. Whether you need to produce flexible films or sturdy pipes, this production line can handle a diverse range of products with precision and quality.

Equipped with a Siemens motor, the Plastic Profile Production Line ensures reliable and consistent performance. The renowned Siemens brand motor delivers power and efficiency, contributing to the overall productivity of the production line.

The extruder barrel material used in this production line is 38CrMoAlA, known for its durability and resistance to wear and tear. This high-quality material ensures the longevity and reliability of the production line, making it a cost-effective investment for long-term production needs.

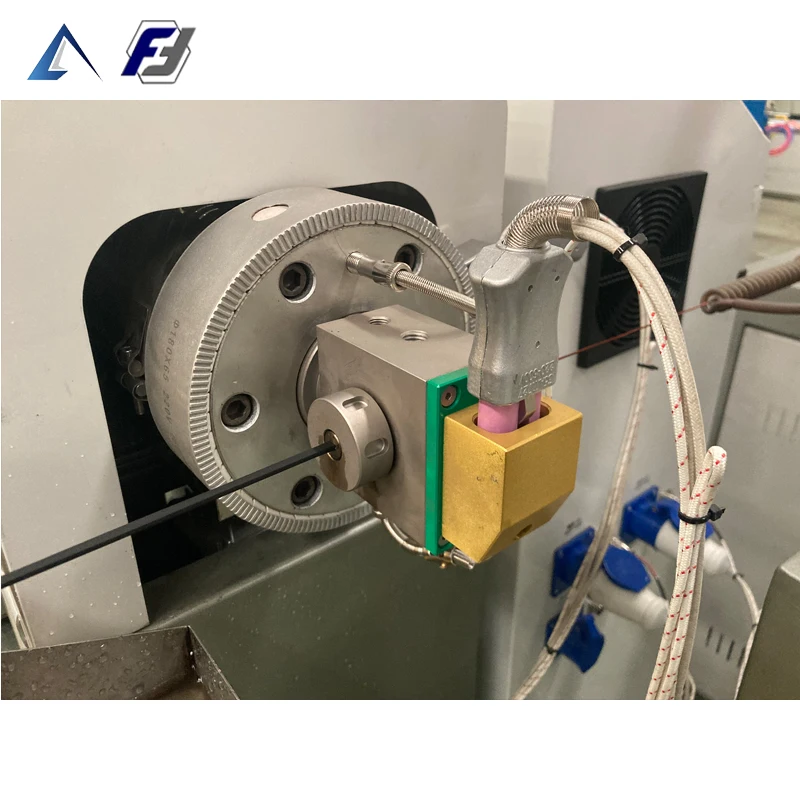

In addition to the main production components, the Plastic Profile Production Line includes auxiliary machines such as die heads for producing various plastic products. These die heads enable precise shaping and molding of plastic materials, ensuring the final products meet quality standards and specifications.

Whether you are producing dual-core nose wire, plastic wire, single core ties, or other plastic products, this production line offers the capabilities and features to meet your manufacturing requirements. The versatility and reliability of the Plastic Profile Production Line make it an ideal choice for businesses looking to enhance their plastic production capabilities.

| Applications | Wires and cables, optical fibers, auto parts, construction materials, etc. |

| Weight | 2-10T |

| Product Examples | Film, pipe, board, thread, tape, granule |

| Product Description | Plastic coating making production line |

| Dimension | 15m*2.8m*2.5m |

| Core Components | Unloading system, pre-treatment system, extruder, coating mold, cooling system, traction device, cutting or winding device and PLC control system |

| Motor | Siemens Brand |

| Temperature Controller | RKC Or OMRON Brand |

| Hard Toothed Gearbox | High Stability And Low Noise |

| Package | Stretch Film Packaging |

ACC Machine's Plastic Profile Production Line (Model: FLD-45N) is a versatile and efficient solution that can be used in various product application occasions and scenarios. With CE certification and originating from China, this production line offers high-quality output for a wide range of products.

The minimum order quantity for this production line is just 1 set, priced at 22000 USD per set. Payment terms are flexible with T/T accepted, and the supply ability is 30 days per set with a quick delivery time of 5-8 work days. The packaging details include wood box packaging for safe transportation.

Product examples that can be produced using this Plastic Profile Production Line include film, pipe, board, thread, tape, and granule. Whether you need PVC packaging ties extrusion production line, dual-core nose wire making machine, or PP PE nose wire making production line, this production line can meet your requirements.

Depending on your needs, this production line can be operated in either automated control or manual control mode. The reduction gearbox used is GUOMAO, ensuring reliable and efficient performance. The package includes stretch film packaging, and the motor is from the reputable Siemens brand.

Our Product Technical Support and Services for the Plastic Profile Production Line include:

- Installation guidance and support to ensure proper setup of the production line.

- Operational training for your team to effectively run the production line.

- Troubleshooting assistance to address any technical issues or malfunctions promptly.

- Regular maintenance services to keep the production line running smoothly and efficiently.

Product Packaging and Shipping:

The Plastic Profile Production Line is carefully packaged to ensure safe delivery to your location. Each component of the production line is securely wrapped and padded to prevent any damage during transportation.

For shipping, we partner with reliable carriers to deliver the product to you in a timely manner. You will be provided with tracking information so you can monitor the progress of your delivery.

Q: What is the brand name of the Plastic Profile Production Line?

A: The brand name is ACC Machine.

Q: What is the model number of the Plastic Profile Production Line?

A: The model number is FLD-45N.

Q: What certification does the Plastic Profile Production Line have?

A: It has CE certification.

Q: Where is the Plastic Profile Production Line manufactured?

A: The Plastic Profile Production Line is manufactured in China.

Q: What is the minimum order quantity for the Plastic Profile Production Line?

A: The minimum order quantity is 1 set.