Product Details

Place of Origin: CHINA

Brand Name: ACC Machine

Certification: CE

Model Number: FLD-45N

Payment & Shipping Terms

Minimum Order Quantity: 1 set

Price: 22000 USD per set

Packaging Details: wood box package

Delivery Time: 5-8 work days

Payment Terms: T/T

Supply Ability: 30 days per set

|

Package:

|

Stretch Film Packaging

|

Customization:

|

Highly Customized Equipment

|

Motor:

|

Siemens Brand

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

Auxiliary Machines:

|

Die Head For Producing Various Plastic Products

|

Hard Toothed Gearbox:

|

High Stability And Low Noise

|

Product Examples:

|

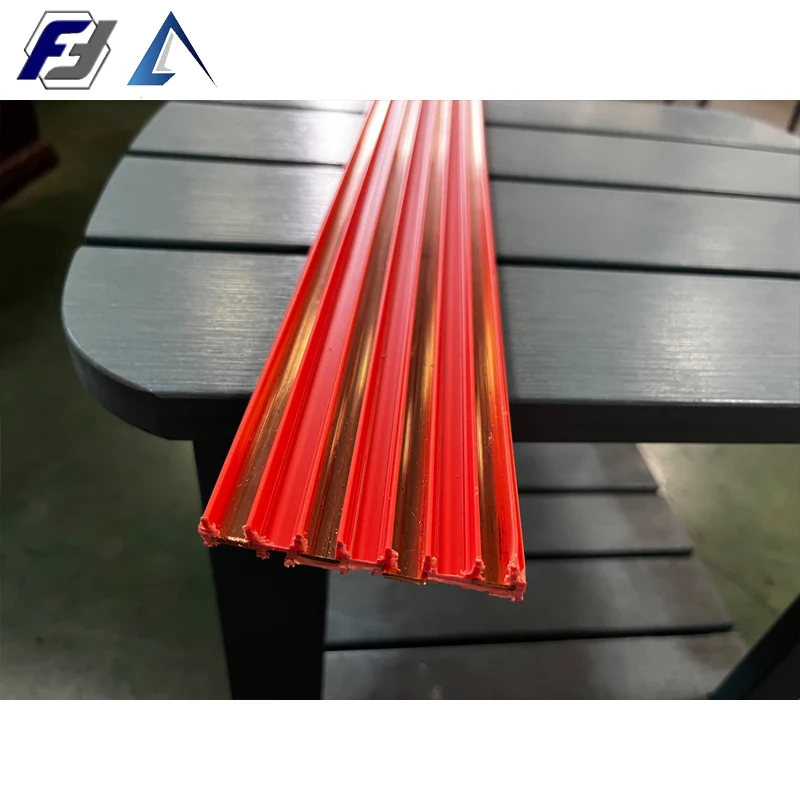

Film, Pipe, Board, Thread, Tape, Granule

|

Cooling Water Tank:

|

Made Of Stainless Steel Material

|

|

Package:

|

Stretch Film Packaging

|

|

Customization:

|

Highly Customized Equipment

|

|

Motor:

|

Siemens Brand

|

|

Applications:

|

Wires And Cables, Optical Fibers, Auto Parts, Construction Materials, Etc.

|

|

Auxiliary Machines:

|

Die Head For Producing Various Plastic Products

|

|

Hard Toothed Gearbox:

|

High Stability And Low Noise

|

|

Product Examples:

|

Film, Pipe, Board, Thread, Tape, Granule

|

|

Cooling Water Tank:

|

Made Of Stainless Steel Material

|

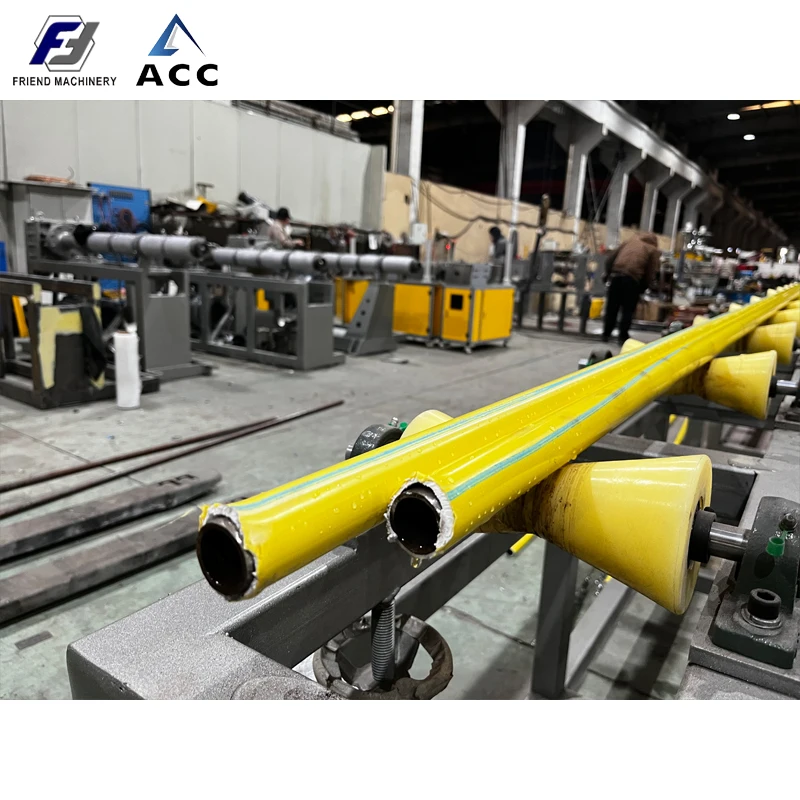

The Plastic Profile Production Line is a versatile and efficient machine designed for producing various plastic products such as film, pipe, board, thread, tape, and granule. It is equipped with advanced features and components to ensure high-quality output and smooth operation.

The package of this production line is done using stretch film packaging, which provides excellent protection during transportation and storage. This ensures that the machine reaches the customer in perfect condition, ready for immediate setup and use.

For convenient operation and control, the Plastic Profile Production Line comes with an independent control box. This allows users to easily adjust settings, monitor production progress, and troubleshoot any issues that may arise. Whether the user prefers automated control or manual control, this production line offers flexibility to suit different preferences and production requirements.

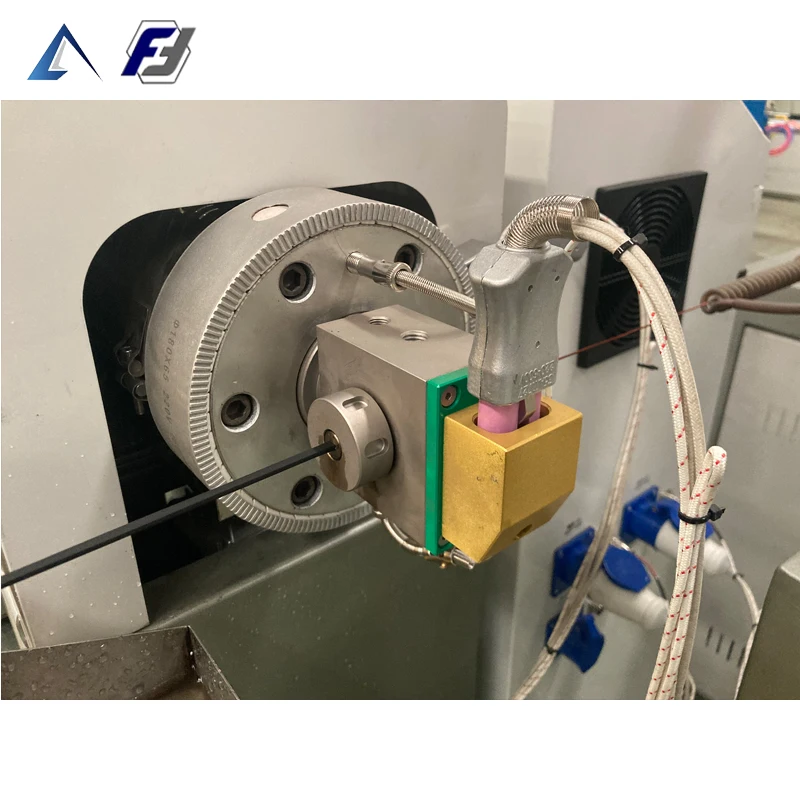

One of the key components of this production line is the extruder barrel, which is made of high-quality 38CrMoAlA material. This material is known for its durability, heat resistance, and corrosion resistance, ensuring a long service life for the machine. The extruder barrel plays a crucial role in melting and shaping the plastic material to create the desired products with precision and consistency.

With the Plastic Profile Production Line, users can easily switch between different product types thanks to its versatility and adaptability. Whether producing film, pipe, board, thread, tape, or granule, this machine delivers consistent results with high efficiency and accuracy.

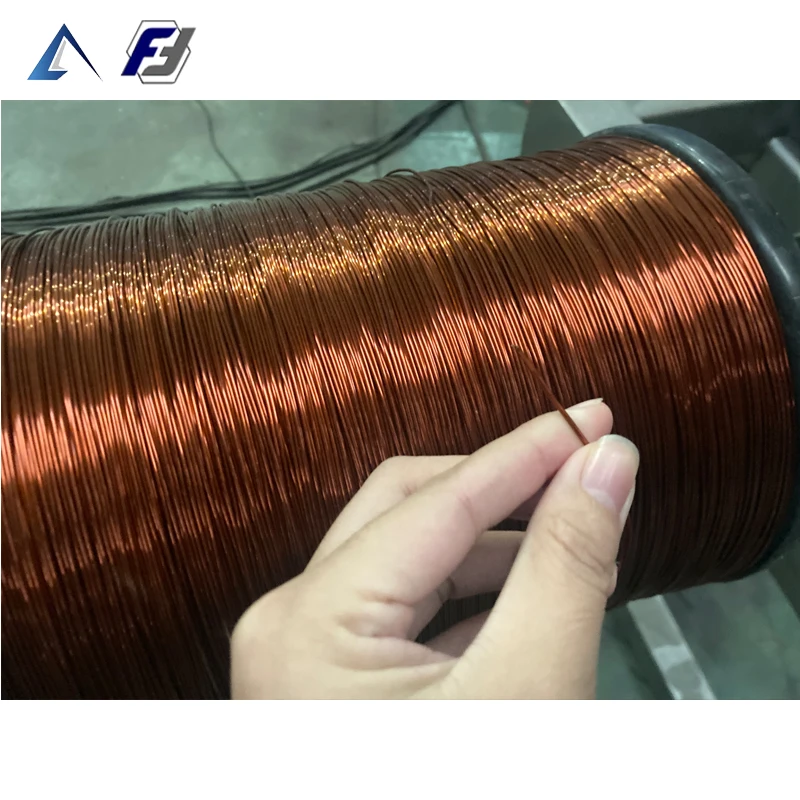

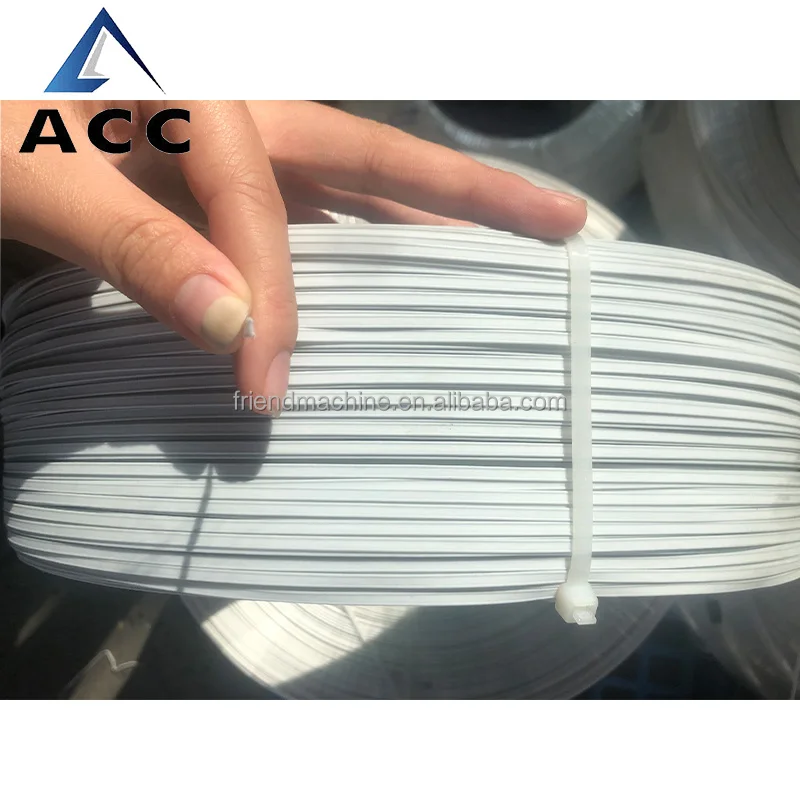

For specific applications such as dual-core nose wire making machine, single core ties making machine, and PVC packaging ties extrusion production line, this production line is capable of meeting the requirements with precision and reliability. Its advanced technology and design ensure that the end products meet the desired specifications and quality standards.

In conclusion, the Plastic Profile Production Line is a top-of-the-line machine that offers exceptional performance, versatility, and reliability for producing a wide range of plastic products. With its stretch film packaging, independent control box, high-quality extruder barrel material, and ability to handle various product examples, this production line is a valuable asset for businesses looking to enhance their plastic manufacturing capabilities.

| Output Capacity | 40kg/ Hr |

| Package | Stretch Film Packaging |

| Control Box | Independent Box |

| Core Components | Unloading system, pre-treatment system, extruder, coating mold, cooling system, traction device, cutting or winding device and PLC control system |

| Weight | 2-10T |

| Cooling Water Tank | Made Of Stainless Steel Material |

| Product Examples | Film, pipe, board, thread, tape, granule |

| Reduction Gearbox | GUOMAO |

| Dimension | 15m*2.8m*2.5m |

| Type | Automated Control Or Manual Control |

ACC Machine's Plastic Profile Production Line, model FLD-45N, is a versatile and efficient solution for a variety of product application occasions and scenarios. This production line is ideal for manufacturing a wide range of plastic profiles, including steel wire coating plastic, PP PE nose wire, and single core ties. With its CE certification and origin in China, this equipment offers high quality and reliability for your production needs.

The Plastic Profile Production Line from ACC Machine is suitable for various industries and applications. It can be used in the production of steel wire coating plastic, PP PE nose wire, and single core ties, making it a valuable asset for manufacturers in the wire and cable, packaging, and construction industries. The equipment's single screw extruder and high stability, low noise hard toothed gearbox ensure precision and consistency in the manufacturing process.

Key components of this production line include the unloading system, pre-treatment system, extruder, coating mold, cooling system, traction device, cutting or winding device, and PLC control system. The independent control box allows for easy operation and monitoring of the production process. Additionally, the equipment can be highly customized to meet specific production requirements.

With a minimum order quantity of 1 set and a price of 22000 USD per set, the Plastic Profile Production Line offers cost-effective production capabilities. Payment terms are flexible with T/T options, and the supply ability is 30 sets per month with a delivery time of 5-8 work days. The equipment is packaged securely in wood boxes for safe transportation.

The Product Technical Support and Services for the Plastic Profile Production Line include:

- Installation guidance and support

- Training for operators and maintenance personnel

- Troubleshooting assistance

- Regular maintenance and service contracts

- Upgrades and enhancements for improved performance

Product Packaging and Shipping:

The Plastic Profile Production Line will be carefully packaged to ensure safe delivery. Each component will be securely wrapped and placed in a sturdy cardboard box with appropriate cushioning materials to prevent any damage during transit.

For shipping, we partner with reliable logistics companies to guarantee timely delivery to your specified location. The package will be labeled clearly for easy identification and tracking.

Q: What is the brand name of the Plastic Profile Production Line?

A: The brand name is ACC Machine.

Q: What is the model number of the Plastic Profile Production Line?

A: The model number is FLD-45N.

Q: What is the certification of the Plastic Profile Production Line?

A: It is CE certified.

Q: Where is the Plastic Profile Production Line manufactured?

A: The product is manufactured in China.

Q: What is the minimum order quantity for the Plastic Profile Production Line?

A: The minimum order quantity is 1 set.